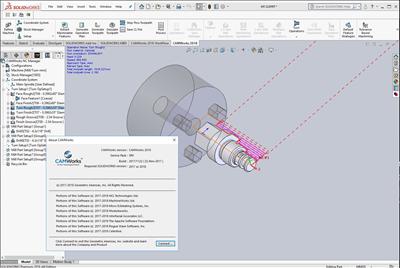

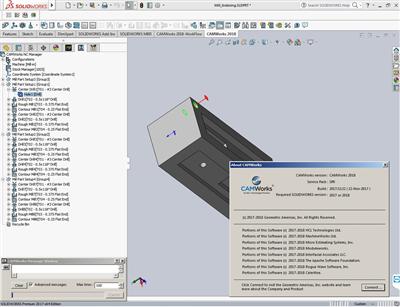

CAMWorks 2018 SP0 | 2.9 Gb

GeometricPLM have launched their new version of CAMWorks 2018 SP0. This release delivers many enhancements and improvements, most created in direct response to customer requests and focuses on helping you program the parts in faster and easier way.

What's New in CAMWorks 2018 - SP0:

General

- CAMWorks NC Editor for viewing/editing post-processed G-code

- Improved Workflow for inserting new operations interactively

- Simplified Rebuild Process that eliminates User intervention

- Option to save default Operation Parameters from CAMWorks User Interface

- Aligning Bounding Box stock for Mill/ Wire EDM with a Coordinate System

- Simulation Toolbar revamped to Toolpath simulation Property Manager Page

Mill

- Improved Part Perimeter Feature Definition dialog box

- Mill Feature Recognition in increasing order of Z level depth

- 'Sort Features' Command to sequence Mill Feature Types and Instances

- Subroutine options on the Posting tab of Machine node

- Enhancements to VoluMill Toolpaths

- Option to choose output order of toolpaths in Assembly mode in Setup tab of Machine Node

- Option for Mirroring Toolpaths at Mill Part Setup Level

- Assigning Max Feedrate of machine as Feedrate for Non-cutting Moves of VoluMill Toolpaths

- Defining Curve Projection Direction for Multiaxis Mill Operations

- Additional options in Entry/Retract Tab for Multiaxis Operations

- New option for Front Shift parameter in Axis Control Tab for Multiaxis operations

- Side Extensions parameters for Extend/Trim in Finish Tab for Multiaxis operations

- Advanced 3 Axis Toolpath Generation Method

- Preview images that graphically represent Point to Point & 2.5 Axis Mill Operation Parameters

- Preview images that graphically represent 3 Axis Mill Operation Parameters

- Assigning Max Feedrate of machine as Feedrate for Non-cutting Moves of VoluMill Toolpaths

Turn/Mill-Turn

- Defining User Defined Turn Inserts from a SOLIDWORKS part or component part of an Assembly

- Defining User Defined Turn Holders/ Boring Bars from a part or Assembly Components

- Defining Coordinate Systems for Main and Sub Spindle from Machine Node itself

- Generate Turn Finish toolpaths based on program point of the insert

- Preview images that graphically represent Turn Operation Parameters

Technology Database

- New User Interface option for TechDB

- SQLite Database type now supported for TechDB

- Assigning Tapping operation to Hole features in Features & Operations Form of TechDB

Note: For the full list of new and improved features, please refer to the release notes located in the folder of your CAMWorks 2018 SP0.

About CAMWorks for SolidWorks. CAMWorks was the first fully integrated computer-aided manufacturing (CAM) solution designed exclusively to operate in SOLIDWORKS® and the first to offer knowledge-based, feature recognition, and associative machining capabilities within SOLIDWORKS.

CAMWorks uses the same SOLIDWORKS geometry to generate toolpaths to ensure the part you machine is the same part you've modeled. Toolpath simulation allows users to compare "as designed" parts to "as machined" parts. The part model-to-toolpath associativity in CAMWorks increases machining productivity and lowers manufacturing costs by eliminating time-consuming CAM system rework due to design updates.

CAMWorks eliminates the drudgery of CNC programming with Intelligent Machining through automation. Pioneered by Geometric Technologies, this suite of tools automates the generation of toolpaths based on a knowledge-based database. It eliminates hours of complex programming through Automatic Feature Recognition (AFR) that automatically defines prismatic machinable features, while the TechDBTM (Technology Database) defines machining operations to automatically generate accurate toolpaths at the click of a button.

CAMWorks machining modules include: 2½ Axis Mill, 3 Axis Mill, Turning, Mill-Turn with 5 Axis Simultaneous Machining Support, 4/5 Axis Simultaneous Machining, and Wire EDM.

About GeometricPLM by HCL Technologies. A specialist in the domain of engineering solutions, services and technologies. Its portfolio of Global Engineering services, Product Lifecycle Management (PLM) solutions, Embedded System solutions, and Digital Technology solutions enables companies to formulate, implement, and execute global engineering and manufacturing strategies aimed at achieving greater efficiencies in the product realization lifecycle.

On April 1st 2016, Geometric got into an agreement with HCL Technologies to transfer of its business to HCL Tech by way of demerger, except for its 58% share in the joint venture with Dassault Systèmes (3DS) (3DPLM Software Solutions Limited (3DPLM)). The transition has become effective on March 2nd 2017, after seeking all statutory approvals.

Product: CAMWorks

Version: 2018 SP0 build 2017/1122 (22-Nov-2017)

Supported Architectures: x64

Website Home Page :

www.camworks.com

Language: multilanguage

System Requirements: PC

Supported Operating Systems: Windows 7even or newer

Software Prerequisites: DS SolidWorks 2017-2018

Size: 2.9 Gb

Recommend download скачать Link Hight Speed | Please Say Thanks Keep Topic Live

Uploadgig https://uploadgig.com/file/download скачать/e0892c3bbD2faD98/nmepn.part1.rar https://uploadgig.com/file/download скачать/1adD322a759282c9/nmepn.part2.rar NitroFlare https://nitroflare.com/view/B8F981A040F4D09/nmepn.part1.rar https://nitroflare.com/view/23BDF3FE1DA33A7/nmepn.part2.rar Rapidgator https://rapidgator.net/file/455591889dfad810f0b177944127eff8/nmepn.part1.rar.html https://rapidgator.net/file/34cbc0602efb3006c143de6f94a5f429/nmepn.part2.rar.html